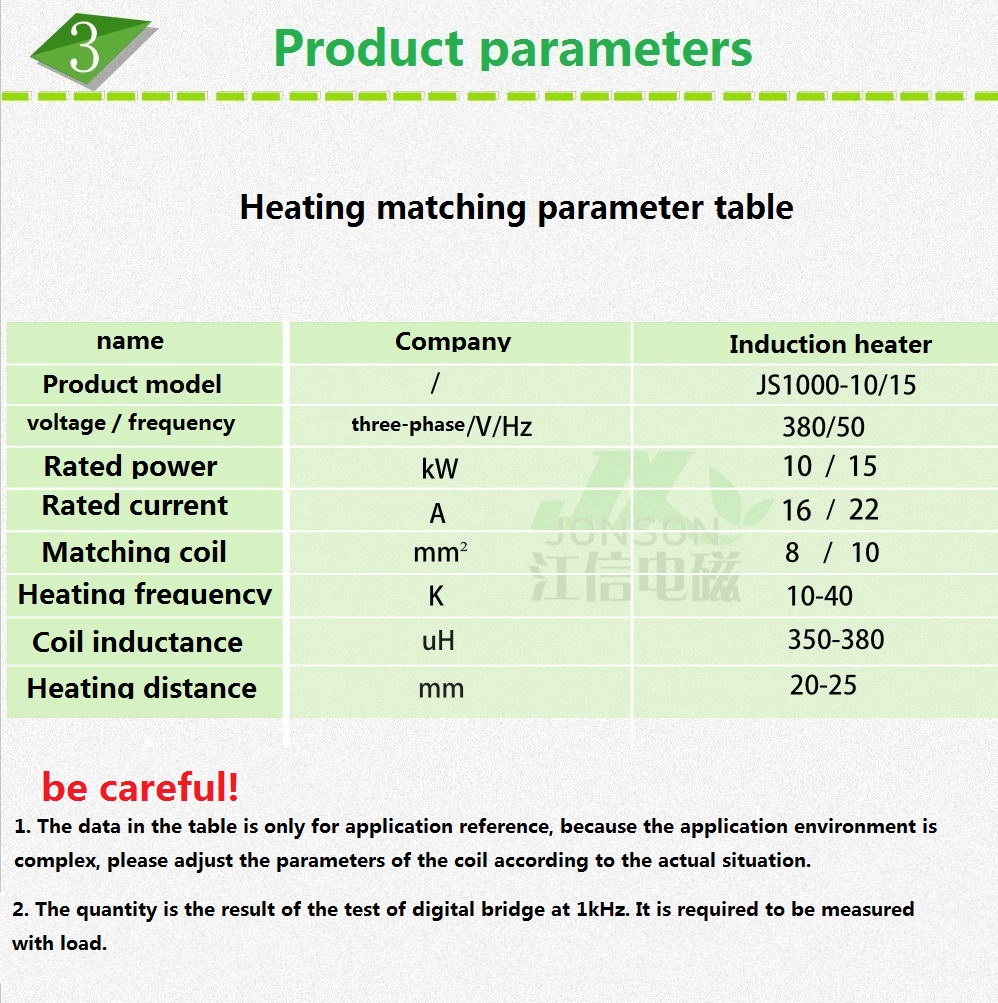

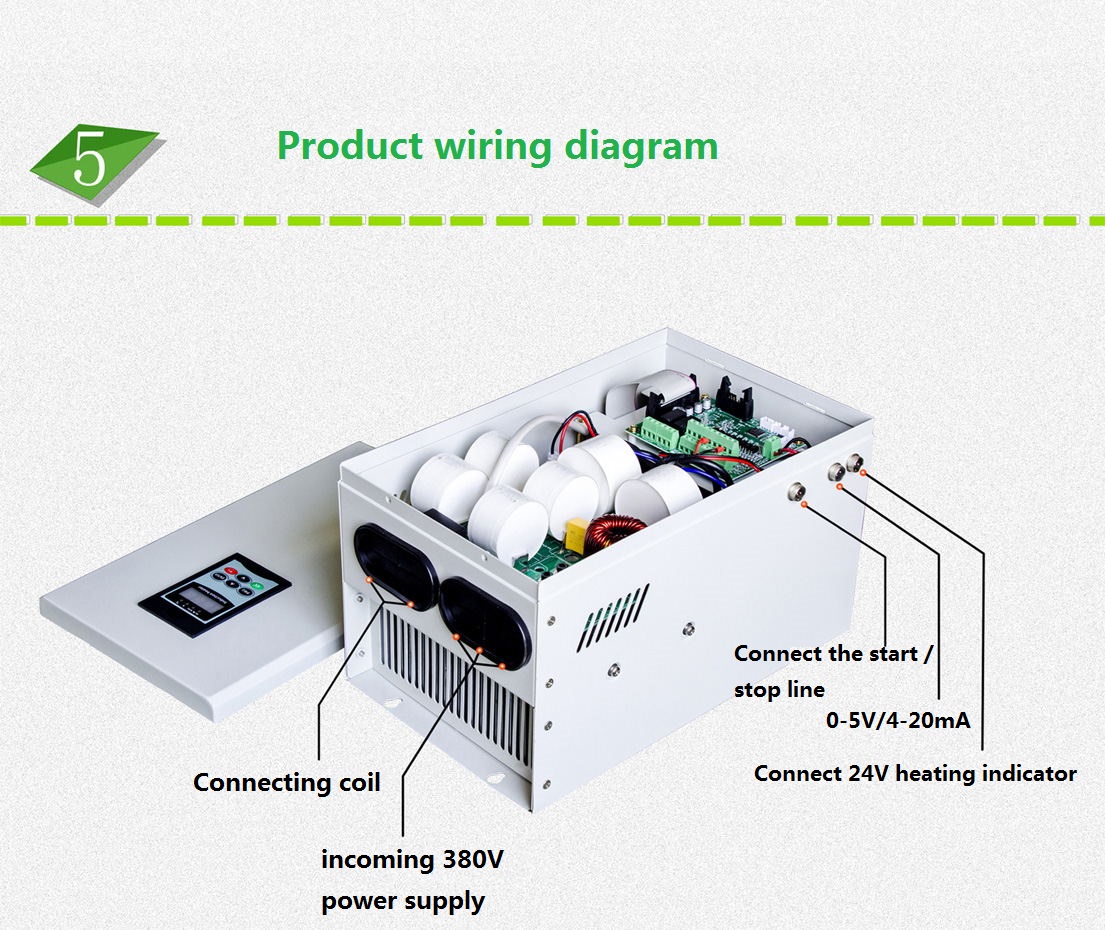

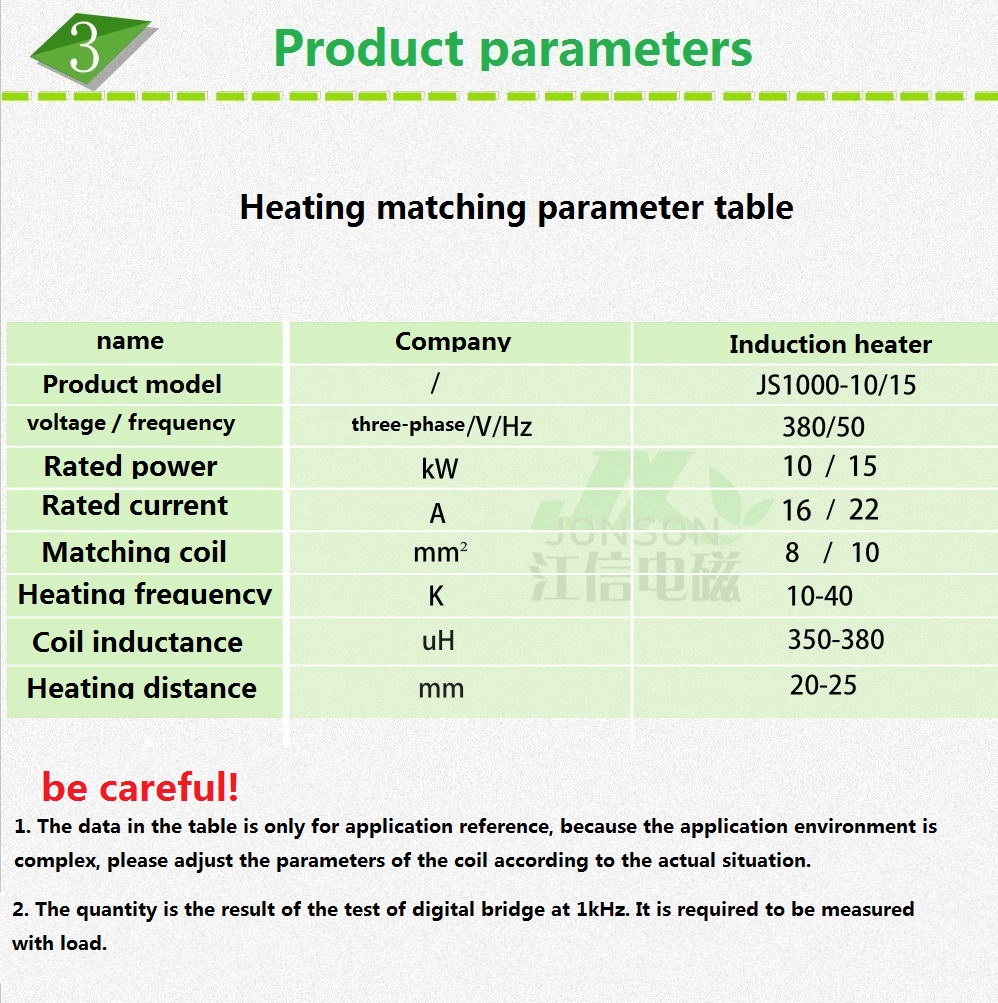

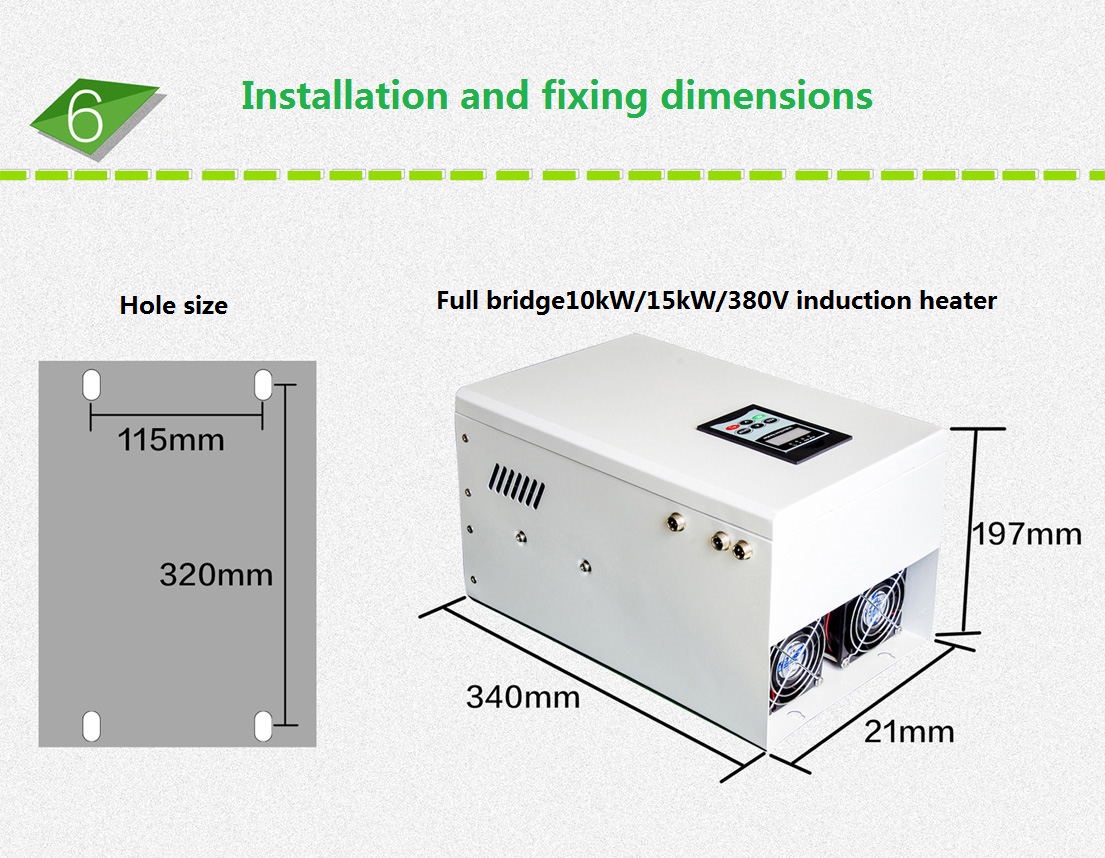

Full bridge10kW/15kW/380V induction heater Basic Info:

rated power:10KW/15KW Three-phase 380V

Rated input current:10KW (14-15A) 15KW (20-22A)

Rated output current:10KW (25-30A) 15KW (30-35A)

Rated voltage frequency:AC 380V/50Hz

Voltage adaptation range:constant power output at 300 ~ 400V

Adapt to ambient temperature:-20ºC~50ºC

Adapt to environmental humidity:≤95%

Power adjustment range:20% ~ 100% stepless adjustment(That is: adjustment between 0.5 ~ 10/15KW)

Heat conversion efficiency:≥95%

Effective power:≥98%(Can be customized according to user needs)

working frequency:5~40KHz

Main circuit structure:Full bridge series resonance

Control System:DSP-based high-speed automatic phase-locking tracking control system

Application mode:Open application platform

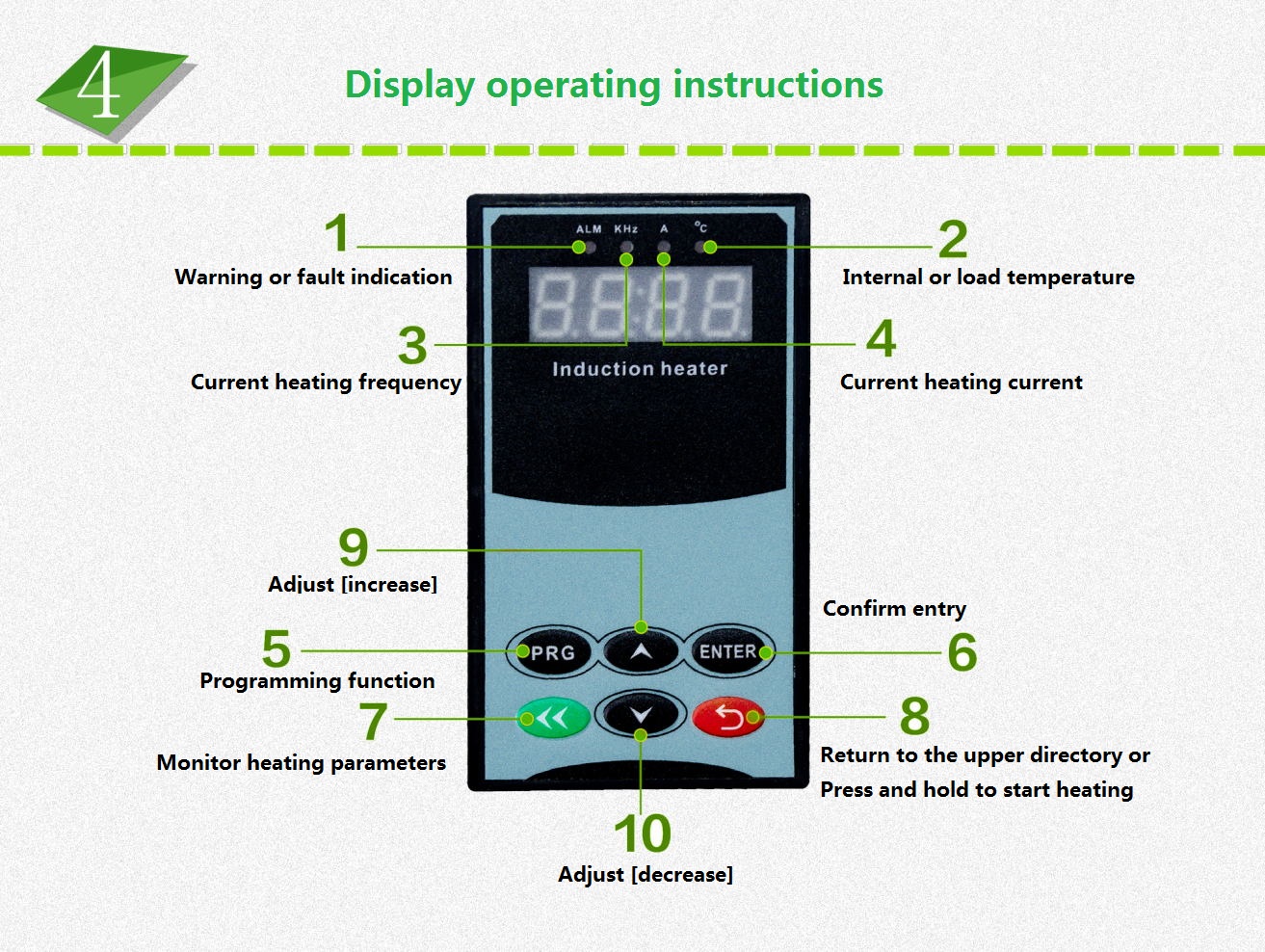

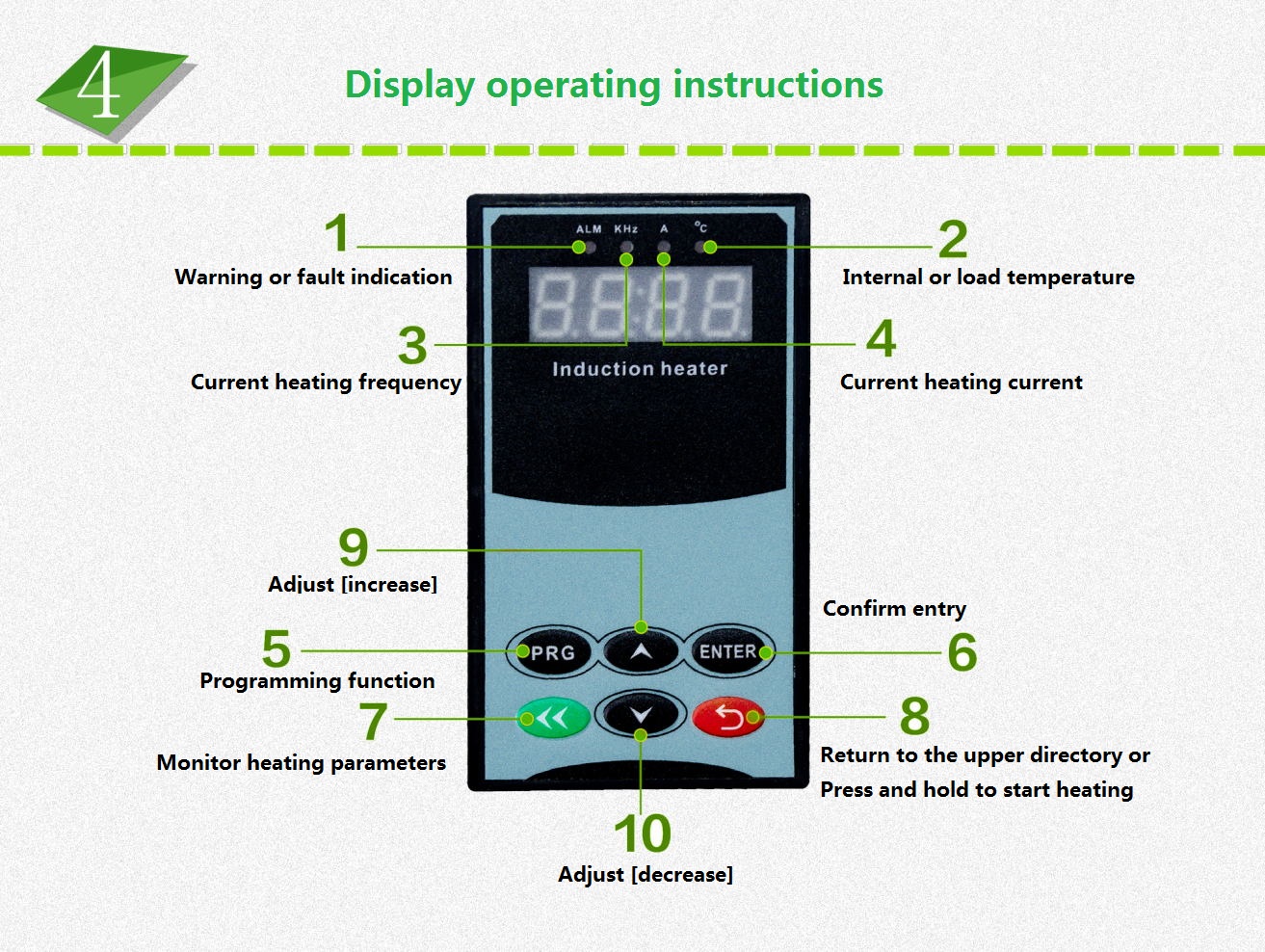

monitor:Programmable digital display

start time:<1S

Instantaneous overcurrent protection time:≤2US

Power overload protection:130% instantaneous protection

Soft start mode:Fully electrically isolated soft start heating / stop mode

Support PID adjustment power:Identify 0-5V input voltage

Support 0 ~ 1000 ºC load temperature detection:Accuracy up to ± 1 ºC

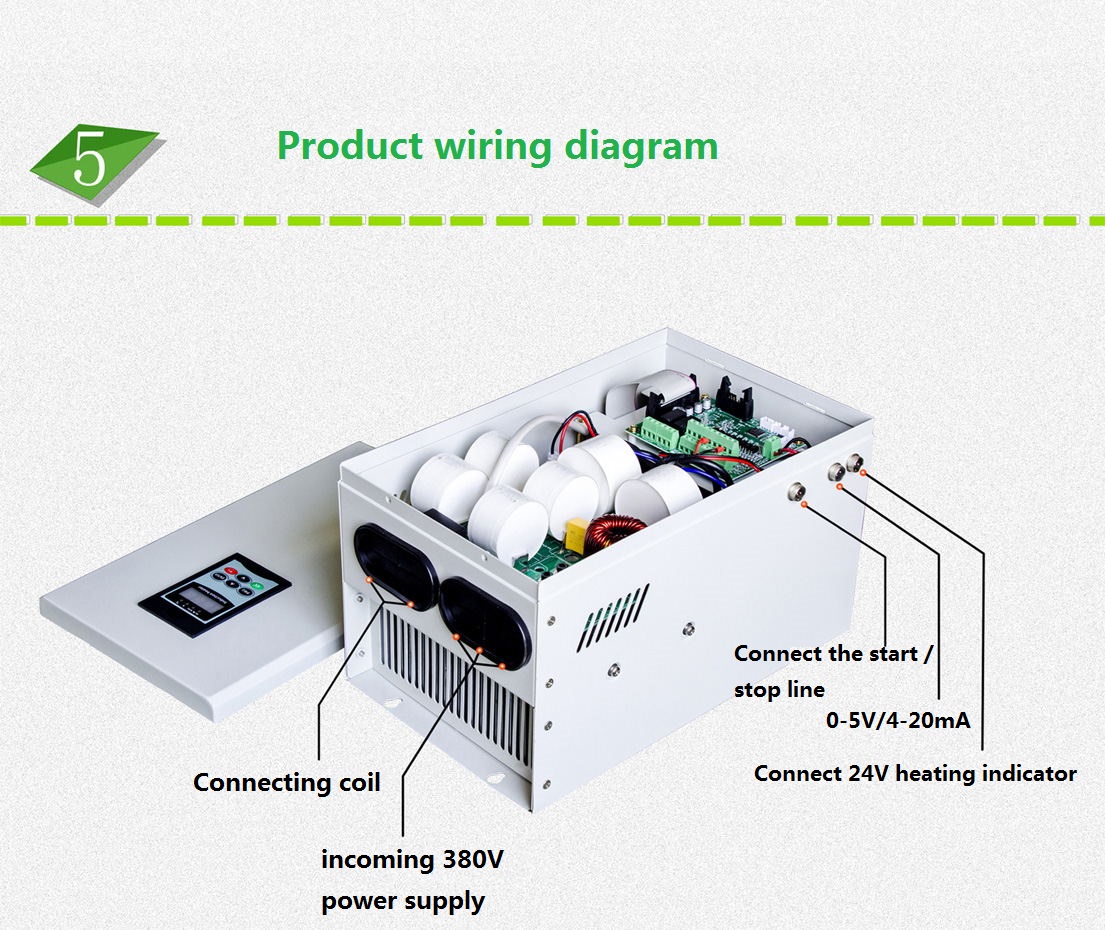

Adaptive coil parameters:10KW 6 square line, length 60~80m, inductance 300 ~ 350uH

Net Weight:10kg

Trademark:Jonson

Transport Package:Carton / Wood Frame

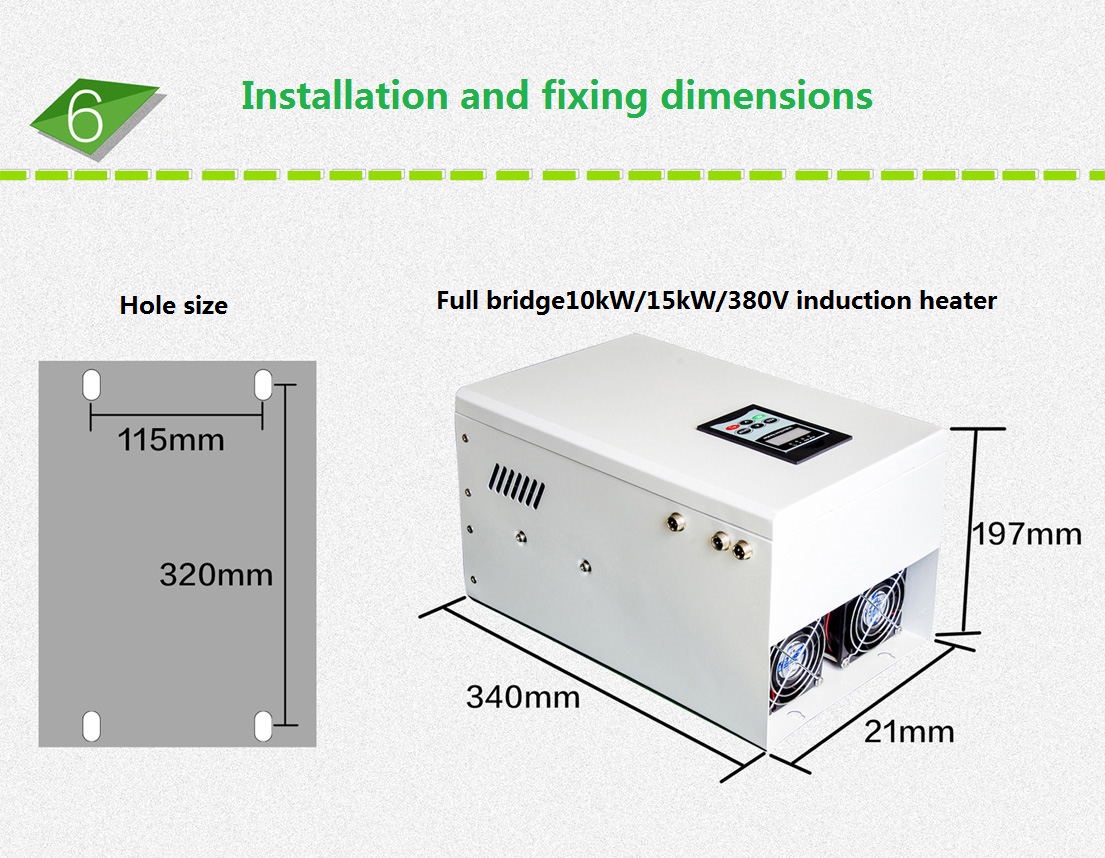

Specification:340mm*210mm*197mm

Origin:Guangdong Province, China

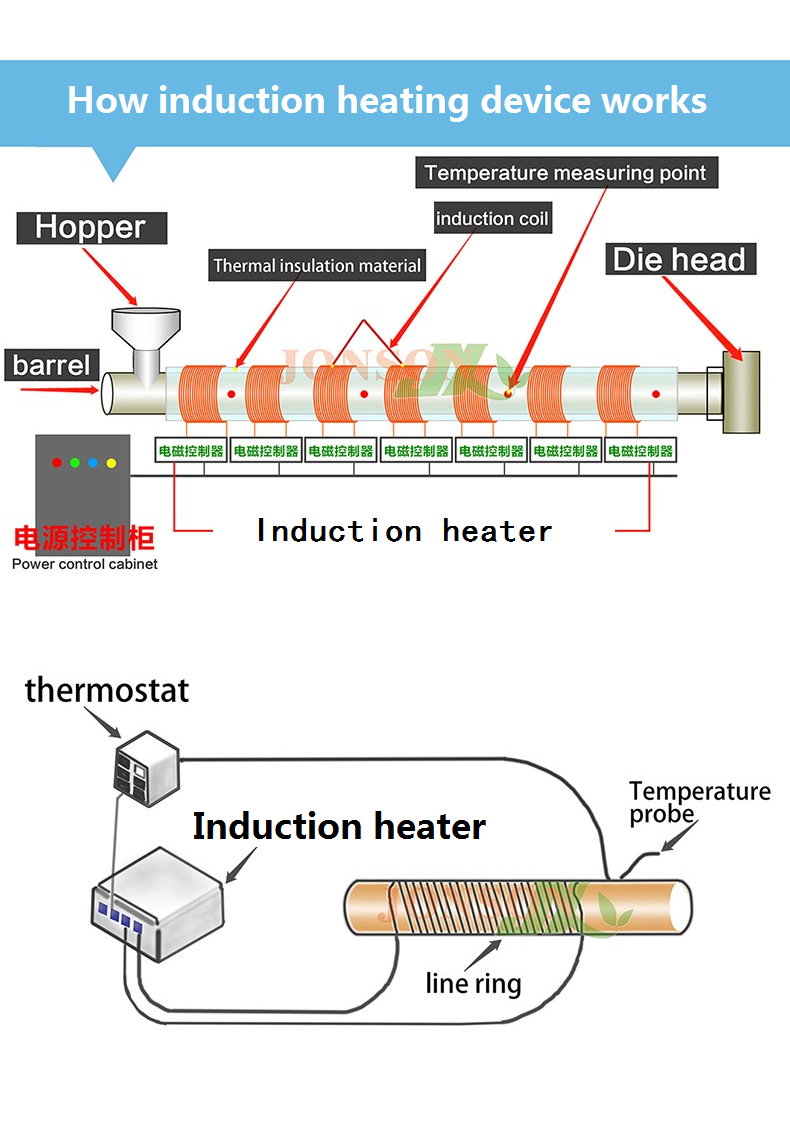

induction heater Description

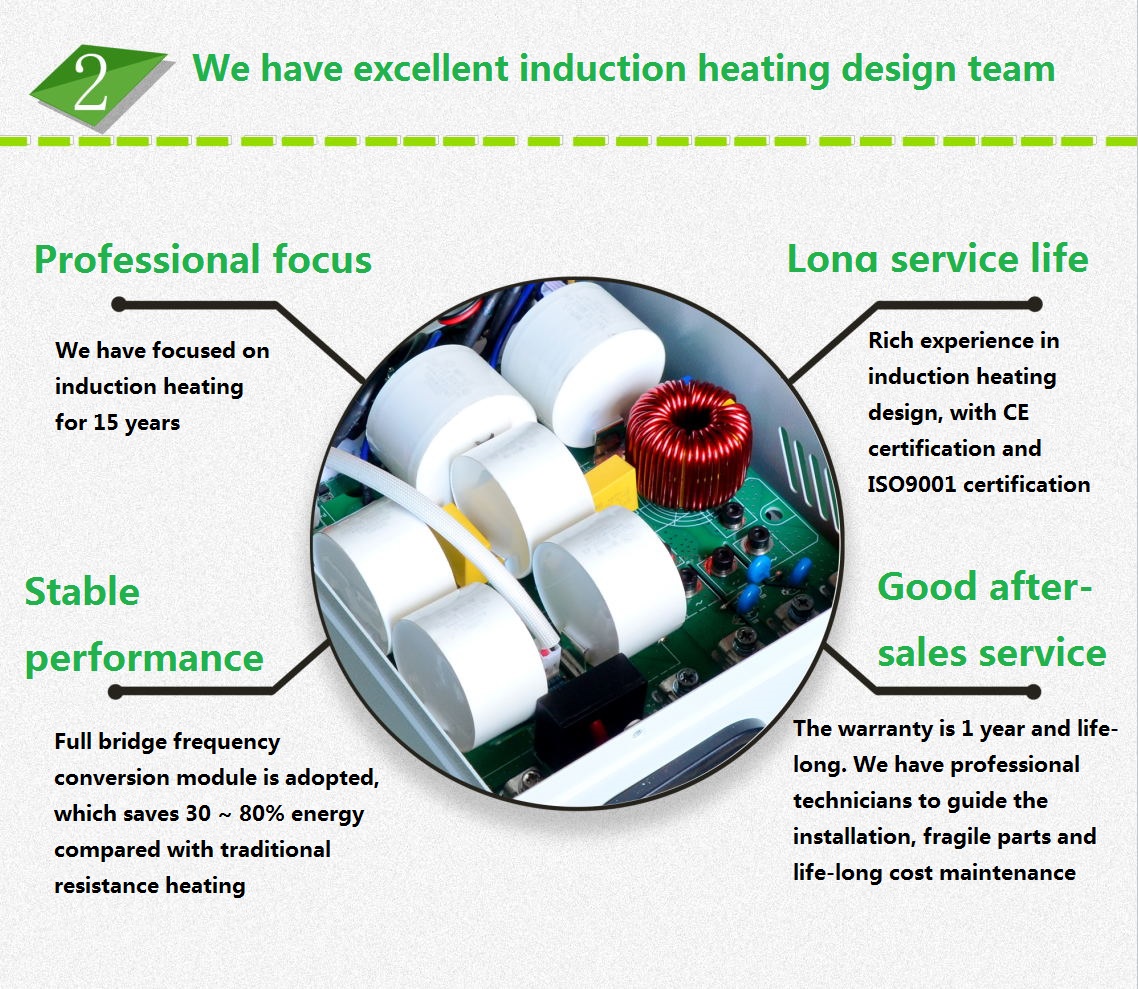

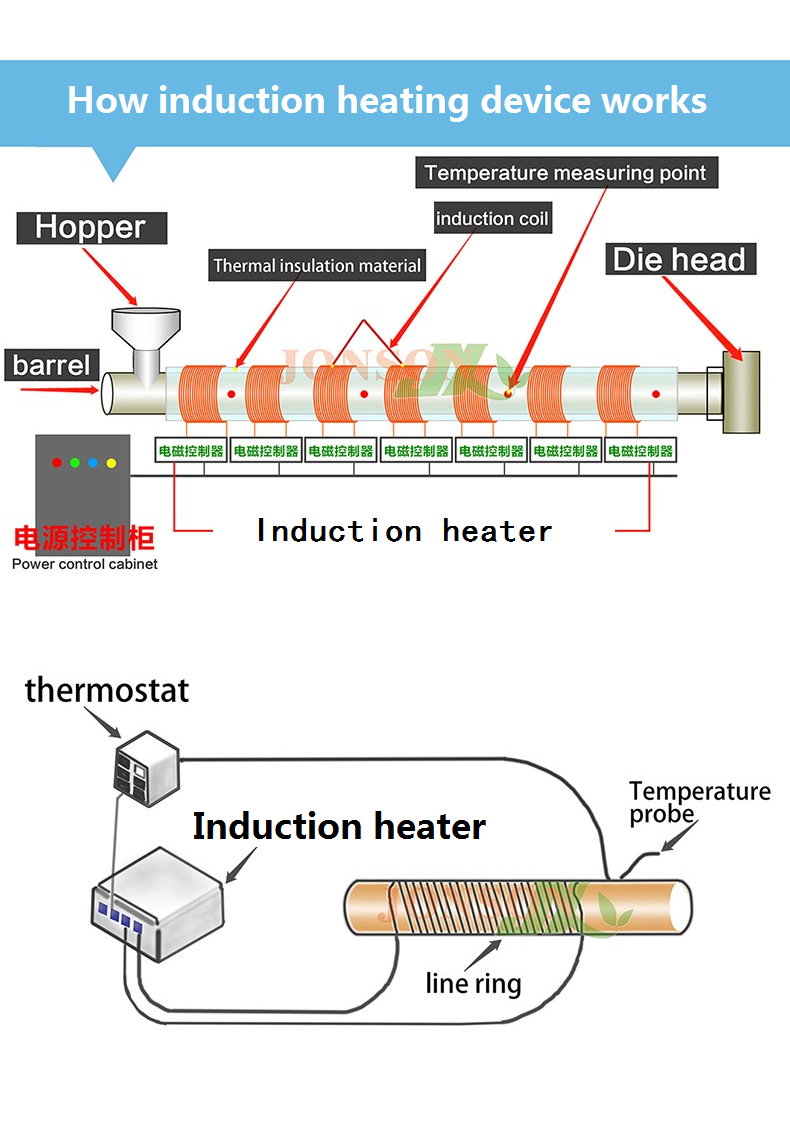

Induction heater 10kw/induction heater 15kw has evolved from a single heating tool to a core process equipment in the era of Industry 4.0. The high efficiency, precision and environmental protection of induction heater 10kw/induction heater 15kw are reshaping the traditional manufacturing industry ecosystem.

User value and cost analysis

1. Induction heater 10kw/induction heater 15kw increases economic benefits

Reduced energy consumption: Taking 1 ton of metal smelting as an example, induction heating saves 80,000-120,000 yuan in electricity bills per year compared to traditional electric furnaces.

Maintenance cost: The life of core components is ssshhh10 years, and the annual maintenance cost is only 1/3 of that of traditional equipment.

Return on investment: The investment recovery period for small and medium-sized equipment (50-500kW) is 1-2 years.

2. Induction heater 10kw/induction heater 15kw increases environmental benefits

Zero emission: no combustion exhaust gas and dust, in line with carbon peak policy requirements.

Space saving: 50% reduction in volume, reducing plant floor space.

3. Induction heater 10kw/induction heater 15kw can improve process

Product quality: temperature uniformity is improved, and the defective rate is reduced by 10%-20%.

Production flexibility: modular design, support for multi-process switching, and adapt to small batch customized production.

Intelligent Control

All digital phase-shifting intelligent control, support RS-485 communication,adopt German IGBT frequency conversion technology. durable and reliable quality

Multiple Protection Functions

IGBT module overheating insulation degree: 80C

Overload capacity is 150%

Under voltage and over-voltage protection

Coil open circuit, short circuit and phase loss protection

Flexible Application

Coil intelligent identification technology automatically adjust the output to achieve the ideal working state

Energy Conservation

With electric energy as fuel, it has no emission andpollution, can work alone, and can use low-costelectricity to save energy greatly

It can be heated for 304 stainless steel materia

We have special induction heating technology, which can heat weak magneticmaterials such as 304, 310, 316 and 310S, which can meet the application ofspecial industries such as food, medicine and chemical industry